Milldam Mine - Derbyshire

The Last Working Mine in Derbyshire

PART 1 - The trip was on and off whether it would be on all week as it was dependant on the last worker ‘Geoff’ who was responsible for installing and maintaining the generators and other electricals on site would be there to let us in, but the night before it was confirmed he'd be there in the morning to sort some stuff out but would be leaving around 12, this meant an early start to ensure we would be able to see the place in its entirety. That morning there was no cafe stop as time was critical and at 7am we were kitting up with some old Hi vis jackets, 4 gas detectors, camera equipment and self rescuers.

Another side to the shutting of this place is that they worked areas further than agreed to, on our first trip here we were shown this underground lake, a short while before here was the start of illegal operations, past this point they were mining where they were not allowed. This wasn’t just a cheeky few metres either, it was around a 10 minute drive to an area of heavy toadstone and natural rifts which were sketchy to say the least. Along the way there was one rift collapse that we got out to check out, among the rubble were bricks presumably from a topside wall. This was expected to happen, the open rifts collapsing and swallowing whatever lies above them, since this visit this whole level (either sub level 4 or 3 i forget which) is now completely under water as the pumps have been switched off.

It's not known yet to what effect leaving this place with most of its water pumps off may have for the village and neighbouring area of Great Hucklow, it will be interesting to see if they all go?or are they seeing if some may need to stay on to prevent further damage.

PART 2 - The second trip was on a sunday evening under the cover of darkness we climbed around bushes and dropped in unnoticed… or so we hoped. Navigation wasn't too hard and the plan was to head to the furthest accessible part of the mine (the naughty bits) and work our way back snapping photos along the way. The first set of pumps were running and that first bit of light that isn't yours along with the noise of equipment running always makes a nervous situation worse. I was half expecting a worker to be there tinkering away, so with lights off we slowly crept up round the corner just in case.

It was all clear and as expected the lights and noises going on were nothing out of the ordinary. I had a feeling that the water was flowing faster than last time and i remembered a conversation i had between me and a previous worker who was showing us round “When they do leave all the pumps will be going off and most of it will be gone, i'd be worried if i lived anywhere above here as well” he said. As we approached the start of a long journey ahead there it was, a sump. Where the water met the ceiling I guessed it was around a 40 minute long walk to where I wanted to get to and with sub level 3 pumps being turned off and removed it was now completely submerged, likely to never be seen again.

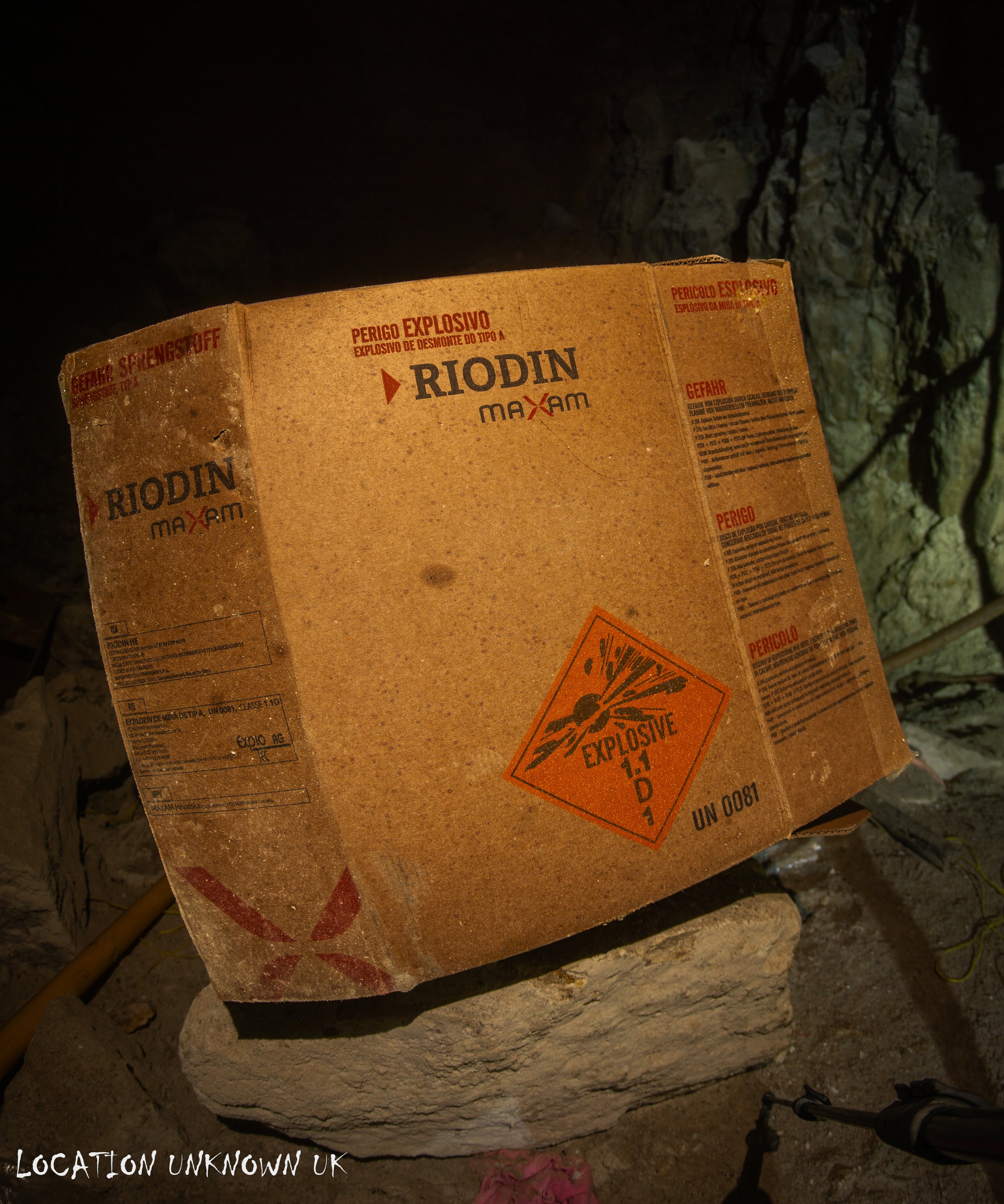

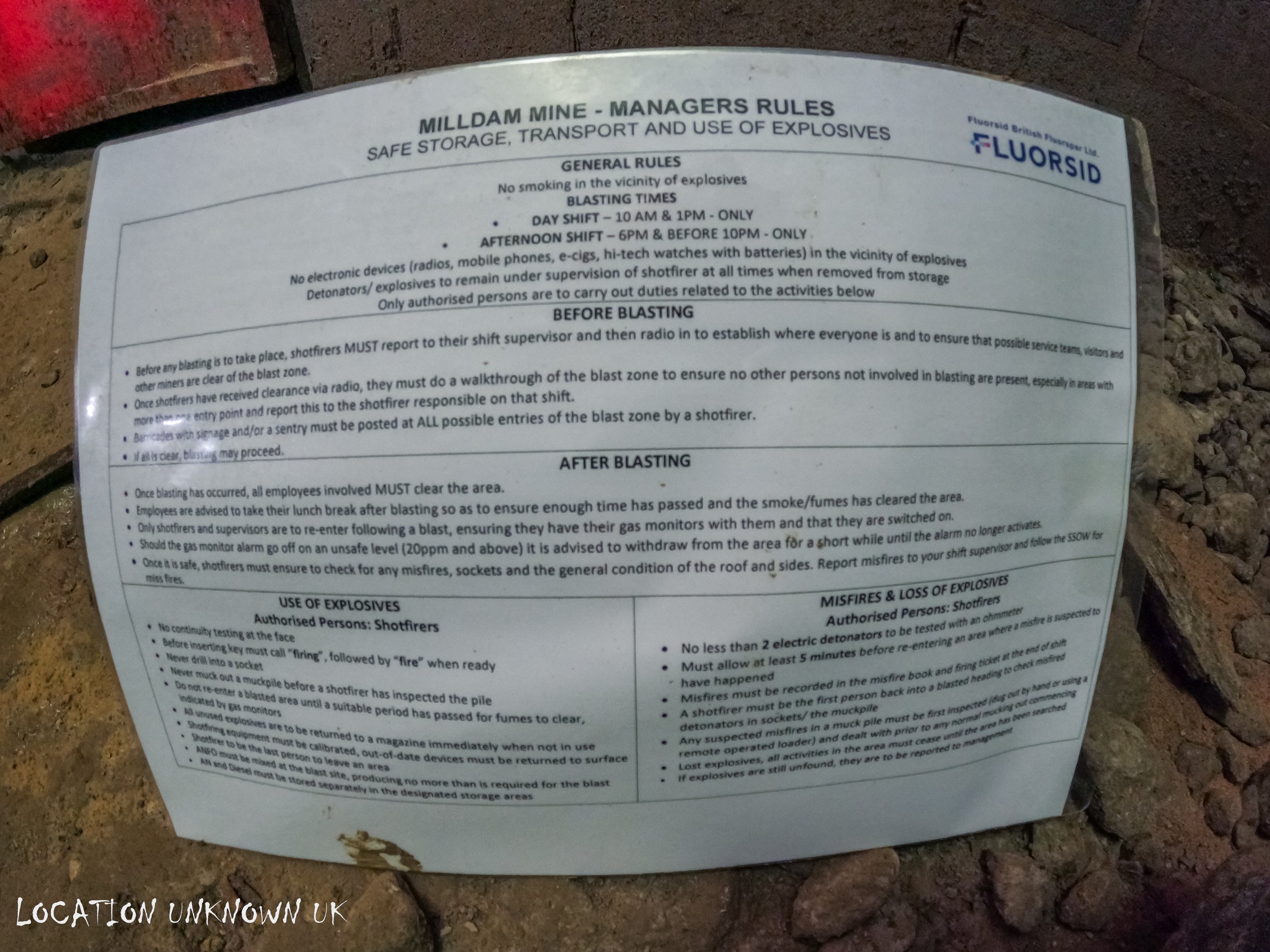

We decided to carry on and explore what we could. Black engine, the old workings and fans were still luckily accessible. We Managed to find a ‘safe storage transport and use of explosives’ sign which described times and safe explosive practices.

It seems that at the moment sub level 1 and 2 pumps are operating maybe to monitor the disturbance caused by switching others off, its uncertain how long things will stay this way but there is at least 1 house i know of that is being monitored for potential disturbance and work is currently being carried out with ground penetrating radar to detect any stope collapses. We headed back out up the long incline hoping to encounter an empty yard and not an unhappy security guard. Luckily the place seemed empty and we made a quick dash for the exit. Mooching down the road and round a corner to our cars it was when I opened my boot that we heard a shout in the distance, it sounded like someone yelling in an aggressive tone. Seeing as we were parked in a remote area with not much around we threw our kit in our boots and I quickly stripped down to my slightly damp thermals underneath and sped away. Unsure if this was a late to the party security or some local somewhere we got away unscathed, it was interesting to see just how quickly the water has reclaimed this place and how much is now lost for good.

History

Mining in Derbyshire has a documented history dating back to 43 AD, almost 2,000 years ago, when the Romans discovered the area was rich in galena (lead), which they called plumbum. However, by late 2023, this ancient industry met its inevitable end. Mining continued throughout the centuries, experiencing a significant boom during the 18th century. The rise of industrialization drove a high demand for lead, essential for materials such as water pipes, roofing, and ammunition. Derbyshire, with its abundant lead deposits, became one of the leading lead-producing regions in the world. By the mid-19th century, however, the lead mining industry began to decline due to several factors. The easily accessible ore had been depleted, and mining deeper underground required costly measures to counteract the water table, such as pumping water out of mines. These operational costs, coupled with economic changes and the emergence of other industries, led to the closure of many mines in the region. While the 19th century saw a sharp decline in lead mining, the demand for fluorspar began to rise. Many old lead mines in Derbyshire were reworked for this mineral, once considered a waste byproduct of lead mining. Fluorspar became the foundation for a new industry, breathing life back into mining in the region. One such example is the Old Mill Dam Mine on the Great Hucklow Edge, which was originally worked for lead until its closure in 1885. Over a century later, in 1985, Mill Dam Mine reopened under Laporte Minerals, which began reworking the old passages for fluorspar along the Hucklow Edge Vein. Operated as a drift mine with a large adit entrance on the edge of Great Hucklow, production resumed in 1991. However, due to high operating costs, mining operations ceased in 1999. Afterward, the mine remained on "care and maintenance" until 2012, when British Fluorspar took over operations. The mine was issued a production permit lasting until at least 2028. The extracted mineral ore was transported to the nearby Cavendish Mill in Stoney Middleton, the UK’s only facility for producing acid-grade fluorspar for the chemical industry. Notably, the Mill Dam Mine is situated on one of the richest mineral veins in Europe. In October 2023, British Fluorspar announced a cessation of operations, citing financial losses. The mine was once again placed on "care and maintenance," though the company expressed optimism that operations could resume in the future, should market conditions improve. In the meantime, ground-penetrating radar is being employed to monitor for any stope collapses.